Sintered Metal Powder Media

Sintered porous metal media, fabricated from a wide variety of metal powders, are widely used for industrial gas and liquid filtration in various processes found in the chemical process, petrochemical, power generation and semiconductor industries. These applications require the use of filtration to meet product contamination needs, for product separation, to protect downstream equipment, or to meet environmental emission regulations. These media – made from various metal alloy powders to meet demanding application requirements – are manufactured in a controlled process by pressing pre-alloyed powder of controlled size and shape into tubes or porous sheet, followed by high temperature sintering.

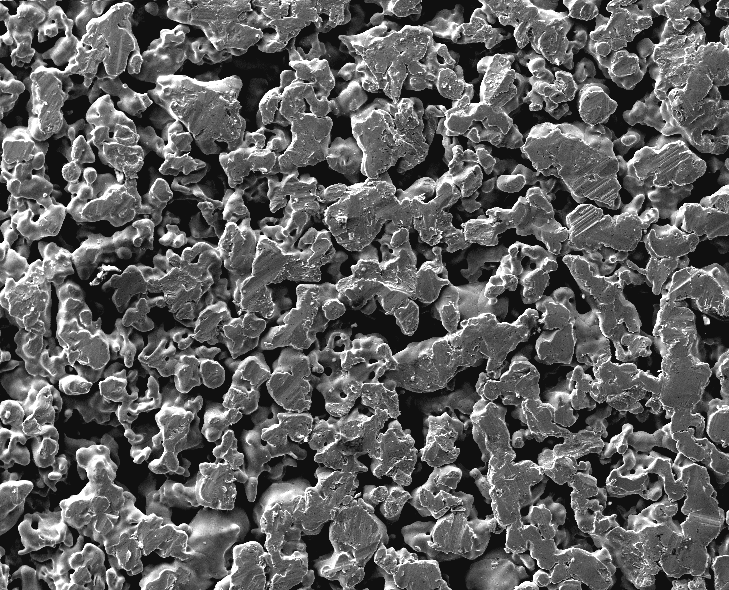

Sintered metal media are offered in a wide range of media grades with mean flow pores ranging from 0.1 to 100m. The combination of powder size and shape, pressing pressure, and sintering operations defines the pore size distribution, strength, and permeability of the porous media. An example of a typical porous structure is shown in the attached scanning electron photomicrograph.

The development of specially designed and engineered sintered porous metal media – with a stable porous matrix, precise bubble point specifications, close thickness tolerances, and uniformity of permeability – assures reliable filtration performance, effective blowback cleaning and long on-stream service life. The sintered metal powder media are available in different alloys – including stainless steel 316L; Hastelloy® B, C-22, C276, N and X; Inconel® 600, 625, and 690; Monel® 400; nickel 200; alloy 20 and titanium – to handle wide-ranging corrosion, temperature and pressure environments. Sintered metal powder media offer a maximum temperature limit of 750 to 1750°F depending on alloy material and atmospheric conditions (oxidizing or reducing).

The proper selection of filter media with appropriate pore size, strength and corrosion resistance enables long-term filter operation with high efficiency particle retention in demanding filtration applications: high temperature, high pressure and corrosive fluids. The primary benefits of sintered metal filters are: strength and fracture toughness, high pressure and temperature capabilities, high thermal shock resistance, corrosion resistance, cleanability, all-welded assembly, and long service life.

Filter cartridges fabricated from sheet or tubes have an all welded construction and can be considered as semi-permanent media. An advantage of metal filters is that they are welded to metal hardware to obtain strong sealed joints. The media can withstand pressure spikes with no evidence of media migration. The inherent toughness of the metal filters provides for continuous, back pulsed operation for extended periods. For high temperature applications, additional criteria such as creep-fatigue interactions and high temperature corrosion mechanisms need to be addressed. Filters with semi-permanent media are cost effective, since such units lend themselves to minimal downtime, closed and automatic operation with minimal operator intervention, and infrequent maintenance.

Porous metal media can be used with either depth and/or surface filtration, but selection of the preferred location for particle capture must be considered and exploited in the appropriate design and selection of the optimal filter media. In the case of depth filtration, the particles are captured within the media, while in surface filtration they are retained on the upstream filter surface where subsequently a cake of particles is formed. Surface filtration is often employed with porous metal media so that the deposited particulate cake can be back-pulsed cleaned in service, thereby greatly extending the online service life of the media. This filter operating life depends on the particulate characteristics (e.g., size, shape, composition) and the filter’s particulate holding capacity, corresponding pressure drop and ability to be cleaned, either on or off-line.

Courtesy of Mott Corporation