Residual Life Indicator: Chemical Vapor Pulse Method

Filter performance failure can result from (1) loss of physical capacity, (2) loss of impregnant reactivity, and (3) loss of mechanical integrity (poor gasket seal) including adsorbent bed integrity (e.g. settling).

The proposed technology utilizes a vapor pulse technique whereby a chemical vapor (tracer) is delivered to the filter under normal operating conditions. The tracer’s role is to identify mechanical defects within the system or to provide information reflecting a change in the capacity (or state of activity) of the adsorbent to remove chemical warfare agents (CWA) and toxic industrial chemicals (TIC). Application of a small vapor pulse of a highly volatile chemical to the inlet of the filter can provide much information as to the condition of the filter in respect to (1) and (3) above and possibly (2).

Chemical properties of a tracer can be designed such as to provide information on the integrity of the system and to identify or minimize mechanical leaks through which an unacceptable amount of CWA or TIC by-passes the adsorbent bed. A chemical tracer test can identify and quantify the size of a leak by comparing the ratio of the tracer associated with a leak to the total quantity of tracer delivered to the filter system.

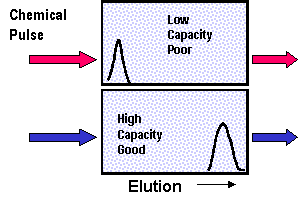

Chemical properties of a tracer can also be designed to provide information on the integrity of the filter other than mechanical defects, such as the adsorptive or chemical (sorptive) activity of the adsorbent. The selected chemical tracer can provide information on the remaining adsorptive capacity of the filter by monitoring the retentivity (peak height, retention time) of the tracer through the adsorbent bed.

Similarly, a selected tracer may be used to characterize the chemical activity of the adsorbent by monitoring the retentivity of the adsorbent for the tracer based on weak interactions that do not significantly diminish the performance of the filter.

The residual life indicator will help minimize logistics, such as filter change-out, as well as ensure that proper protection is afforded by in-place filters on both vehicles and fixed-site systems.

Author

Christopher J. Karwacki and Gregory W. Peterson

Edgewood Chemical Biological Center U.S. Army RDECOM

Team Leader | Chemical Engineer

-

(410) 436-5704 | (410) 436-9794