Porous Metal Filter Media

Most industrial companies that process fluids – such as chemical processing, pharmaceuticals, oil refining, automotive and others- utilize some type of filtration equipment. These filters are typically used to remove particulate contaminants, additives or solid catalysts from the process stream. In many cases, the operating conditions of the process require the use of porous metal filters. Although much higher in cost than “disposable” filters, porous metal filters are often one of few available choices due to these extreme conditions. Common reasons for the use of porous metal filters are high temperatures, high operating pressures and chemical incompatibility with common disposable filters.

There are a variety of metallic filter types available, each with its own features, benefits, and unique performance capabilities. Among the available media, the most commonly used in the process industries are sintered metal powder, sintered fiber metal felt, and woven wire cloth in both un-sintered and sintered forms.

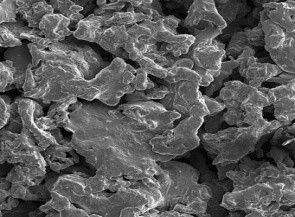

Sintered metal powder media is available in micron ratings as low as 0.1µ. The media has a relatively low porosity, which can result in high differential pressures in some applications. This same low porosity does, however, make this media extremely durable and suitable for use in extremely demanding applications. It is available in a variety of alloys, including 300 series stainless steels, nickel based alloys, titanium and others. The media is most often used in tubular form, and is commonly used in backwash/back pulse systems for both liquids and gases.

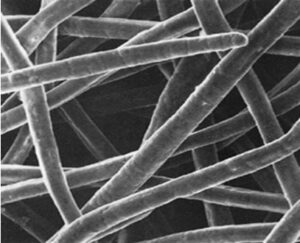

Sintered fiber metal felt media is available in micron ratings as low as 2.5µ and has a very high porosity, which delivers a low pressure drop. The media can be fabricated into tubular form, or pleated to provide increased filtering surface. The media can be configured as a depth filtration medium, and has a much higher dirt holding capacity than either sintered metal powder or woven wire cloth. It can also be configured to function as a surface filtration medium, and can be efficiently backwashed or backpulsed. This media is available in a variety of alloys, including those mentioned above for sintered metal powder. Filtration of molten polymers is a common application.

Woven wire cloth is perhaps the oldest and most geometrically simple form of porous metal media. Available in micron ratings as low as 1.0 µ, and in a variety of alloys, including those noted above for sintered metal powder. The media has a relatively high porosity, and thus a low pressure drop. Unlike sintered metal powder or sintered fiber metal felt, which have tortuous internal pores, woven wire cloth has a virtually straight-line pore structure. Multiple layers of woven wire cloth can be sintered together to enhance strength and durability.

Many factors should be considered when selecting the optimum porous metal media for an application. Among them are the required particle removal rating, the desired clean pressure drop, the ease of cleaning the filter element in place or upon removal, and the alloy required for chemical resistance.

Author

Mark Willingham

Purolator Advanced Filtration

Director of Sales & Marketing

Mark Willingham is Director of Sales & Marketing for Purolator Advanced Filtration with 30 years of experience in porous metal filter products for varied industrial applications.