Pleatable UPE Membrane Media in Pulse-Cleaned Dust Removal Air Applications

Newly developed UPE membrane composites are compared with commercial PTFE membranes in a study being done at Lydall Filtration. UPE has specific performance advantages over PTFE that are impressive.

Media Selection

For initial tests, three media were selected for comparison. These structures are all designed for use in pulse-cleanable cartridges, with processing on blade pleaters. Arioso™ M7001-11 is a Solupor® ultra-high molecular weight polyethylene (UPE) membrane designed for F9/MERV16 efficiency at very low resistance laminated to a 200 gsm, stiff, high permeability spunbond polyester functional support layer. Arioso M3203-11 is a Solupor UPE membrane designed for H12/MIL-SPEC HEPA efficiency laminated to the same polyester functional support layer. Sample A is an industry leading ePTFE membrane coupled with a stiff, calendared spunbond polyester structure.

| M7001-11 | M3203-11 | Sample A | |

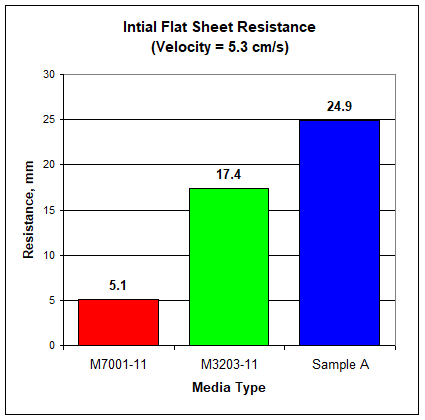

Resistance (5.3 cm/s) | 5.1 mm | 17.4 mm | 24.9 mm |

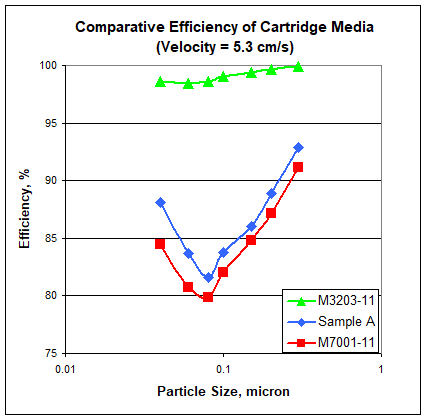

| Efficiency (MPPS, 5.3 cm/s) | 79.9% | 98.4% | 81.6% |

Efficiency (0.3µ, 5.3 cm/s) | 91.2% | 99.9% | 92.9% |

| Thickness (Caliper, 8 psi) | 0.55 mm | 0.60 mm | 0.53 mm |

Figure 1 – Flat Sheet Properties

Comparison of Medias, Flat Sheet

Flat sheet analysis of Arioso M7001-11 showed similar efficiency to Sample A but with almost 80% reduction in initial pressure drop. Arioso M3203-11 showed significantly higher efficiency with a 30% reduction in initial pressure drop. All the structures were similar in thickness.

Residual Pressure Drop

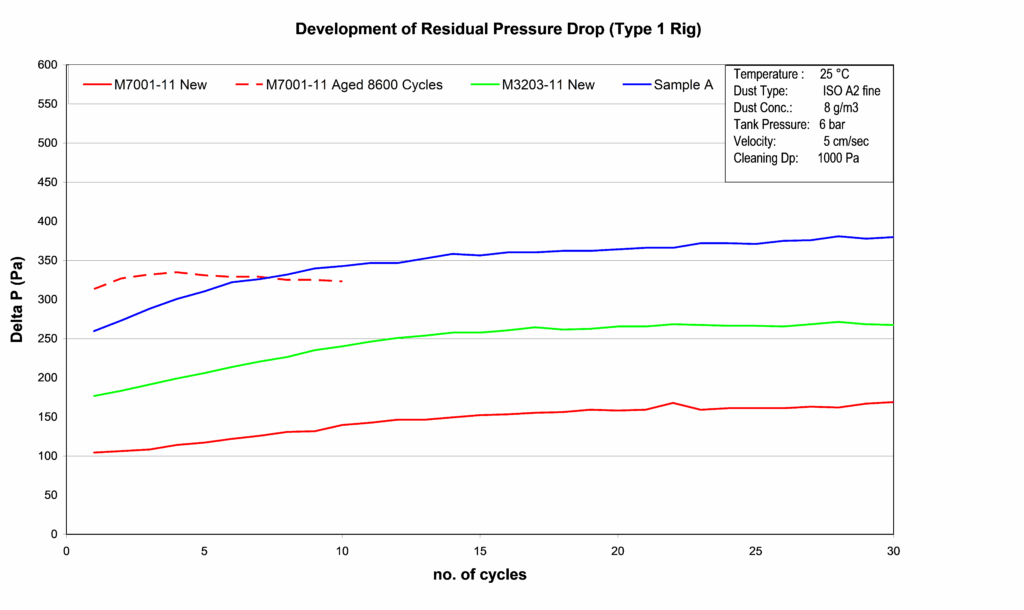

One of the key parameters measured by this testing is the increase in residual pressure drop over time. These tests were performed roughly in accordance with an accelerated version of VDI Guideline 3926 for flat sheet media.

As the media is subjected to dust loading and pulse cleaning cycles, particles gradually build up on and in the media. Media that releases dust more effectively will see less buildup in residual pressure drop, leading to longer times between pulsing, potentially longer media life, and potential energy savings.

As seen in Figure 4, both Arioso media samples start with lower initial pressure drop as compared to Sample A. More testing is required, but the Arioso media samples also seem to be adding residual pressure drop more gradually than Sample A. One item of note is that the aged M7001-11 (having withstood 8600 loading/pulse cycles) is not increasing residual pressure drop following its aging cycle, and at this stage in its life has lower residual pressure drop than the relatively new Sample A.

Other process effects including cartridge construction, pulse frequency and pulse pressure are currently under evaluation and more complete results will be presented at AFS Spring 2011 Conference in Louisville, KY.

Author

Mr. Crosby has over 20 years experience in product design and marketing for water filtration, fluid temperature control, and air filtration across multiple industries. He has a Bachelor of Science from Rensselaer Polytechnic Institute.