Filter Aid to Improve Solid/Liquid Separation Process

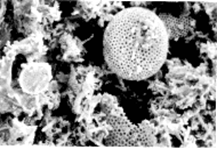

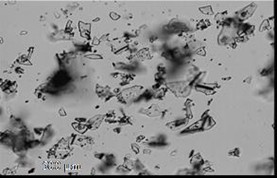

Filter aids are used to solve the problems of slow filtration rate, rapid medium blinding or unsatisfactory filtrate clarity. Filter aids are chemically inert and porous materials which can form cakes of high permeabilities. Traditional filter aids are diatomaceous earth (skeleton of diatoms), perlite (expanded volcano rocks), or cellulose fibers. Other varieties like inactive carbon, polyurethane, fly ash, calcined rice hull, saw dust, or mixtures of above materials are also available nowadays.

The filter aids can be mixed into the suspension (body feed) or used alone to form an initial layer of cake (pre-coat). When used as a body feed, the presence of filter aid makes the cake more porous to increase the filtration rate. A precoat cake prevents the real solids from reaching the filter medium and medium fouling can be avoided. The precoat cake also acts as a deep bed filter to catch the fine particles so the filtrate can be very clear from the beginning of the filtration.

Filtration performance can be improved with filter aid but there is an added cost for purchasing filter aid and the final cake will contain more solids. With body feeds, the cake depth will increase more quickly, lowering the pressure gradient. Therefore, there is an optimum dosage of filter aid. Over dosing will have an adverse effect on the economics and filter performance. Tests are necessary to determine the right kind of filter aid and the optimum dosage.

It needs be remembered that after the filtration it is impossible to separate filter aid from the suspending solids. Therefore, filter aids are only useful when the purity of solids is not a concern.