Every Filtration Media has a Purpose

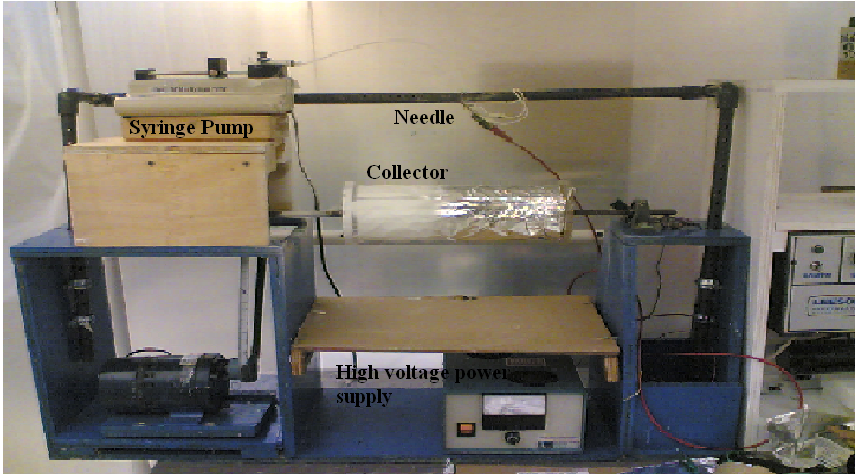

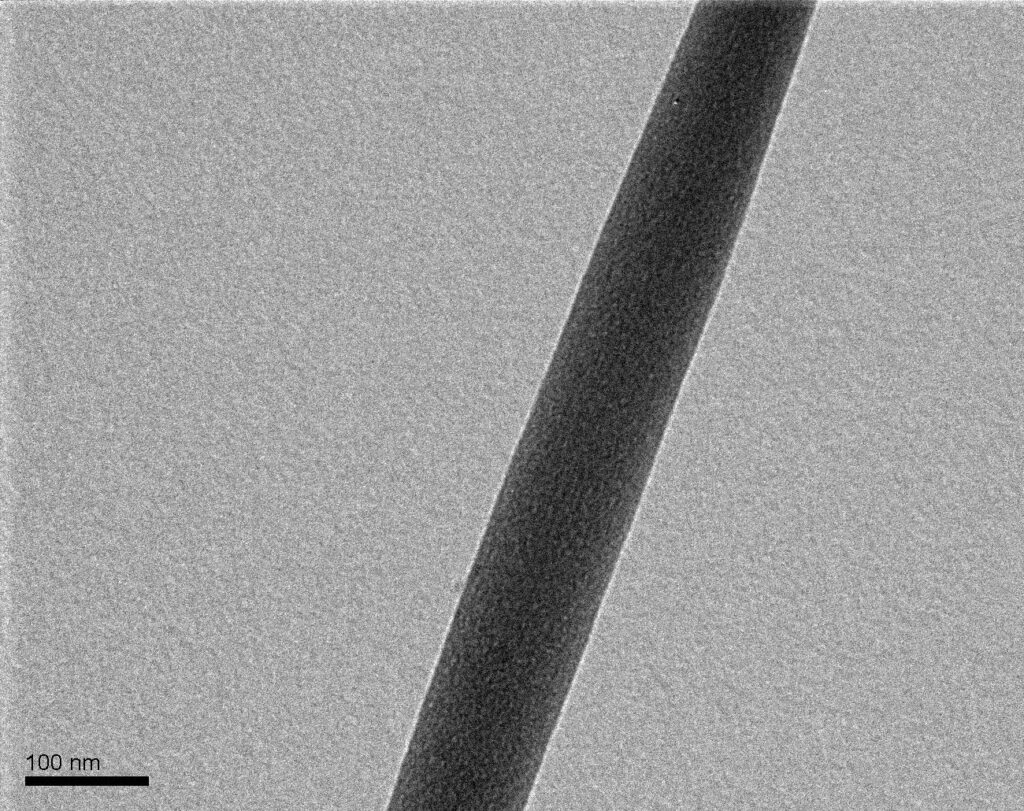

There are eight major different types of filtration media; ceramics, filter aids, monofilament nonwoven fabrics, membranes, metals, porous plastics and wetlaid. Yet, there are other types and many variants of the eight major categories. The list is virtually endless, including new entrants in recent years like nanofiber webs, which many might consider a sub-category of nonwoven fabrics.

No two filter types are made on the same production equipment. For example, nonwoven fabrics cannot be produced on membrane manufacturing lines and filter aids are from an entirely different category of materials and process than media such as monofilament woven fabrics and so on. Filter media companies tend to specialize in one or two filter different media and rarely supply more three or more media types. The majority tend to concentrate on one media category, whether monofilament woven fabric, membranes, metal such as weaving wire cloth or filter aids, as examples. The cost of the production equipment to produce each medium is expensive and the variations of media constructions are so numerous, companies specialize to capture enough volume to fully utilize their equipment.

A somewhat similarly situation exists with filter makers. Filter manufacturers tend to offer a limited number of filter types, RO/UF membrane filter module manufacturers rarely make and sell microporous membrane cartridges and porous plastic producers do not make metal filters from wire cloth. Companies who produce wetlaid media from cellulose or synthetic fiber rarely provide other media. If they do, it’s most often from another division at a different location.

Each media has different functional capabilities and properties. Filters from metal or ceramic are rigid and used in high-pressure applications, such as for polymer filtration or where a corrosive fluid is present. An example would be diesel exhaust filters or high-temperature environments and are almost always capable of being cleaned and reused. Nonwoven fabric media with a few exceptions are used at room to slightly elevated temperatures and have depth holding capability to capture of particulate and are typically single use applications where the filter is subsequently disposed. Certain exceptions are baghouse filters and dust collection cartridges, which are designed to be part of large systems, allowing for in-situ back-pulse cleaning. Microporous membranes are some of the most costly media and always found where extremely fine filtration is required such as in the medical, pharmaceutical or semiconductor industries. Filters from microporous membranes are generally used to retain bacteria whereas reverse osmosis membranes will desalinate seawater and ultrafiltration membrane modules are widely used in food processing.

Wetlaid cellulosic media with binder fibers has been the mainstay in transportation filters for lube oil and engine air-intake filters for many years. Cellulose is capable of taking the environment under the hood of automobiles and trucks and is relatively inexpensive. Fiberglass wetlaid media is found in high-pressure hydraulic filtration, because the glass fibers are non-compressible and provide excellent dirt-holding capacity. Fiberglass fiber can be made quite fine, even sub-micron in diameter and is the go-to material for HEPA filers for clean rooms, coalescing media and certain laboratory filters.

Monofilament woven fabrics (think yarns like fishing line or weed-wacker cord) is a surface filter, like wire cloth, is woven from very fine diameter yarns from 20 microns up to 1,000 microns in diameter for a very wide range of applications from high-end blood and ophthalmic pleated filters to sludge dewatering belts found in many municipal treatment facilities.

Porous Plastic filtration media consists of fine plastics powders molded into porous rigid shapes, often using hydrophobic polymers for use in medical devices, automotive lamp assemblies and battery vents. In recent years porous plastics are molded into membrane tube supports for use in waste water and pleated pool and spa filters.

Obviously, one media does not fit all needs when it comes to filtration.

References

- Reneker DH, Yarin AL, Fong H, Koombhongse S. Bending instability of electrically charged liquid jets of polymer solution in electrospinning. Journal of Applied Physics 2000; 87: 4531-4547.

- Li D, Xia Y. 2004. Electrospinning of Nanofibers: Reinventing the Wheel? Advanced Materials.16:1151-1170.

- Tsaia PP, Schreuder-Gibson H, Gibson P. 2002. Different electrostatic methods for making electret filters. Journal of Electrostatics.54:333–41.

- Huang Z.M, Zhang Y.Z, Kotaki M and Ramakrishna S. 2003. A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Composites Science and Technology. 63: 2223-2253.