Coagulation and Flocculation to Improve Solid/Liquid Separation Process

Chemical treatment means the use of coagulants or flocculants to enhance the agglomeration of solid particles in the slurry to form larger and denser flocs so they will settle faster or be filtered more easily.

The term coagulation and flocculation are mixed used. However, most people refer to coagulation as the process of changing the electrolyte concentration to de-stabilize a colloid system so the particles are not repulsing one another and form agglomerates. For this purpose, compounds like ferrous sulfate, polyaluminum chloride, aluminum sulfate and lime which provide Fe+2, Al+3, Ca+2 are commonly used coagulants.

Flocculation means the use of long chain organic polymers to form bridges between solid particles. Synthetic chemical flocculants are more commonly used. They are mostly derivatives of polyacrylamide and can be anionic, cationic or non-ionic.

Coagulants and flocculants can be used alone on in combination with others. Similar to filter aids, there are optimum dosages for chemical treatments, and tests need to be conducted to determine the best chemical and its optimum dosage.

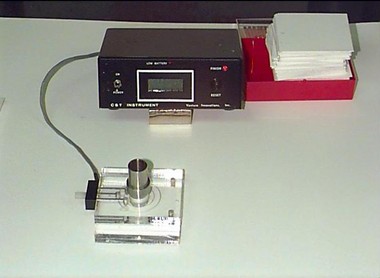

The test can be conducted with the so-called Jar Testing apparatus, which is the most commonly used method to select chemical conditioners. It provides a quick screen by observing the floc size, settling time, clarity of the supernatant and the sediment height. Capillary suction time (CST) is used to screen conditioners for filtration applications. This method uses the capillary suction force generated by filter paper to mimic a cake filtration process. The lower the CST, the faster the filtration process.