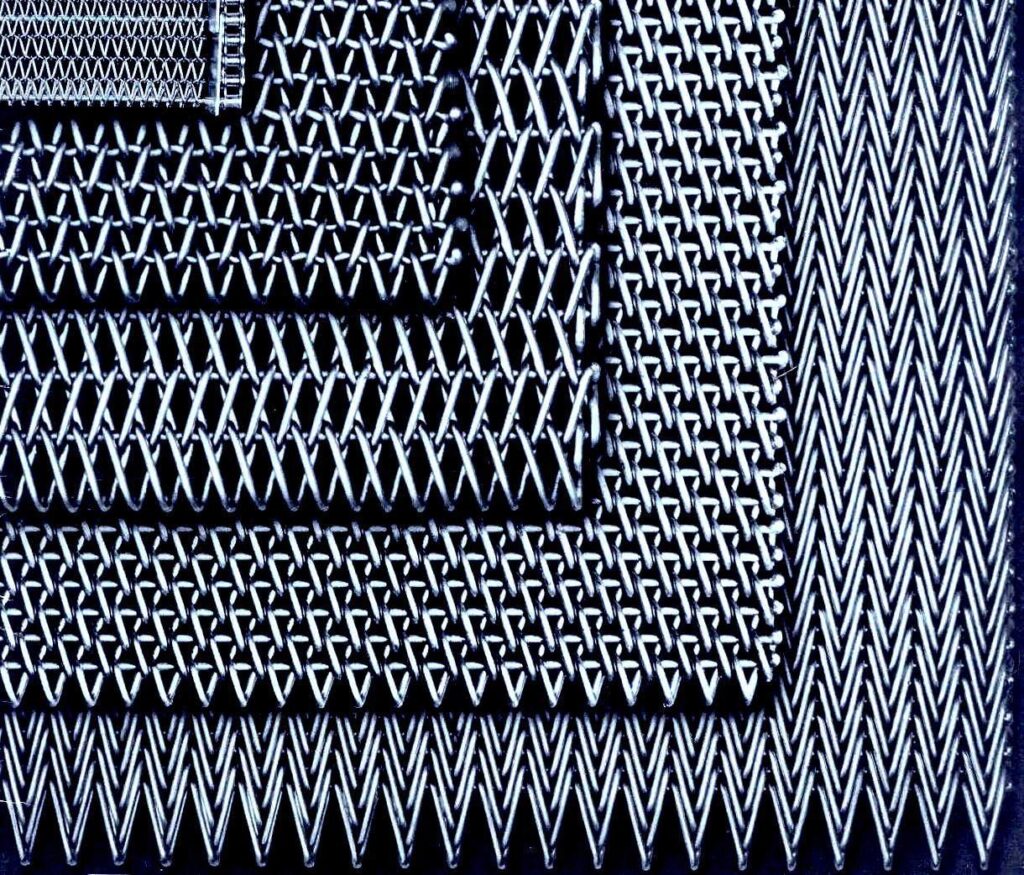

Wire Cloth Media

The marketplace for performance wire cloth in the United States is $120 – 130 million. Epoxy coated carbon steel is not counted in this total. Because such a large percentage is imported, this value may vary depending upon exchange rates. The largest percentage of performance wire cloth consists of stainless steel, which ranges as low as $0.50 to over $80.00/sf with the majority priced in the $1-4 sf range. Wire cloth is primary imported from the Far East, including China, South Korea and Japan to a lesser degree. Precision woven wire cloth for high-end applications commonly comes from Europe with Germany, France and Switzerland leading. There are a number of distributors of wire cloth in North America, whereas the European companies sell direct from their sales office and warehouses. USA weavers tend to produce specialty wire cloth from high-value alloy metals and contract runs to order.

Wire Cloth is available in many popular alloys from aluminum, copper, nickel, stainless steel, titanium, Hastalloy etc. Each metal generally yields different cost and performance benefits. Stainless steel wire is quite common and often comprised of many component metals, including as chrome, nickel and manganese, allowing for different characteristics which exhibit varying properties, including the ability to be sintered to itself or stainless steel supports.

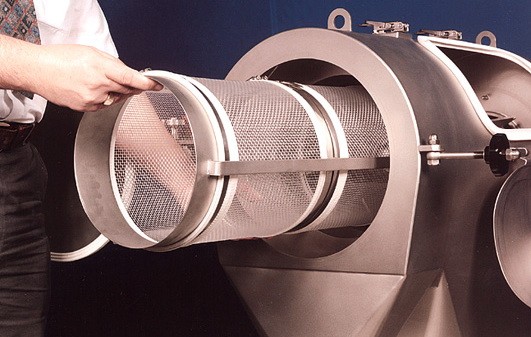

Applications for wire cloth include polymer filters for film extrusion and textile fiber spinning. Other applications include leaves and/or septums as support for filter aid cake formation and pleated filter elements and widely in filter candles. Other uses include strainers, rotary and vibratory sifter screens for process industry, screens in kitchen faucets and general particulate removal in water purification in the pulp and paper, coal, coke, sewage treatment and sugar industries. In some coalescers, PTFE coated wire cloth enhances efficiencies. Applications are extensive and far broader than space allows here.