What is Forcespinning™ Technology?

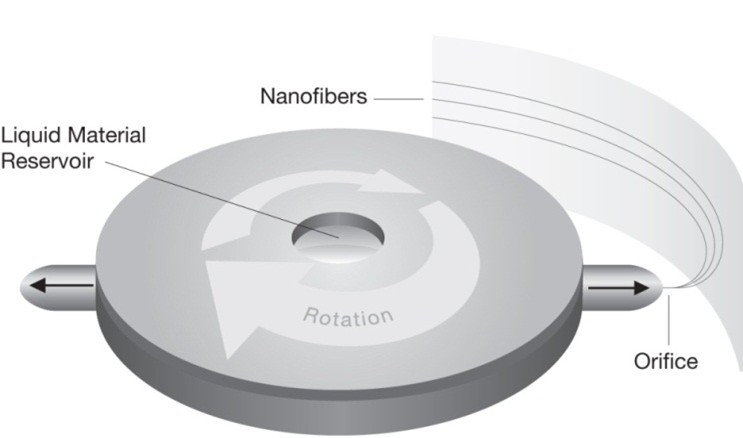

The processing of polymers into nanofibers offers a broad range of applications in areas such as filtration, catalysis, tissue engineering scaffoliding, photonics and sensors. The centrifugal nanofiber processing called ForcespinningTM allows for fabrication of both solution and melt spun nanofibers [1-4]. Figure 1 shows the schematics of fiber formation using ForcespinningTM technology. The polymer solution or melt are forced through the orifices of the spinneret by applying centrifugal force. As polymer solution or melt is ejected through the orifices, continuous polymer jets are formed and are stretched into formation of fine web of fibers due to applied centrifugal force and shear force acting across the orifice tip. The web is collected on the custom designed collector system. The morphology and fiber diameter are determined by controlling the operating parameters such as: solution concentration (in case of solution spinning), melt viscosity (for melt spinning), rotational speed of the spinneret, orifice size, temperature of the spinneret (for melt spinning), and collection system. By varying these parameters, fine control over the fiber diameter and morphology is possible.

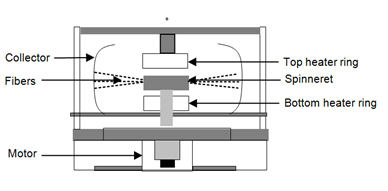

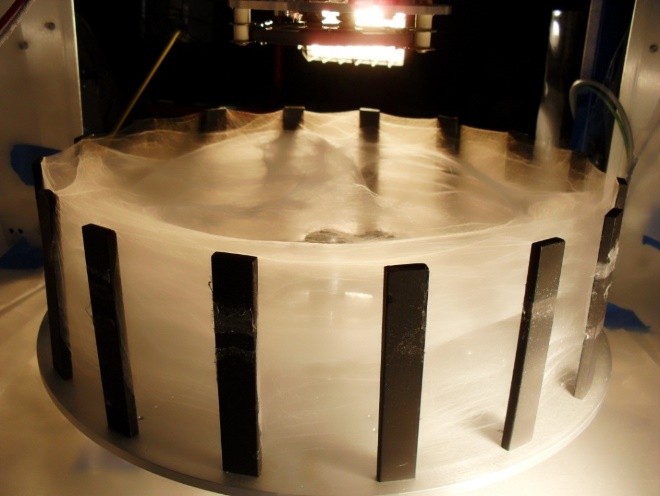

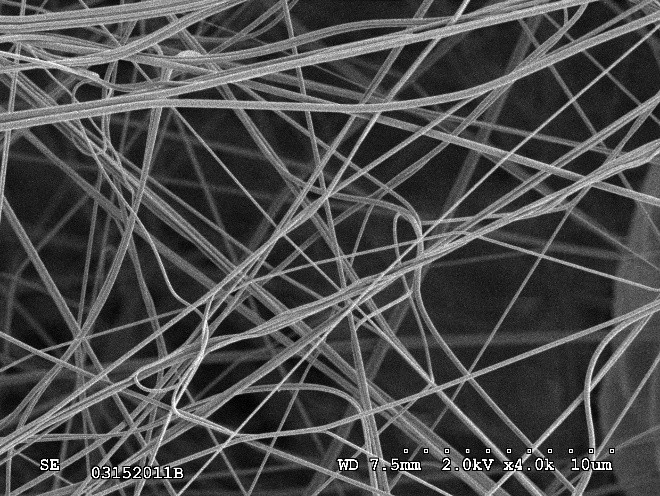

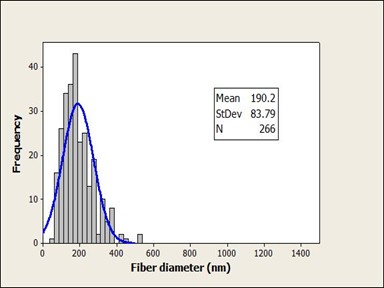

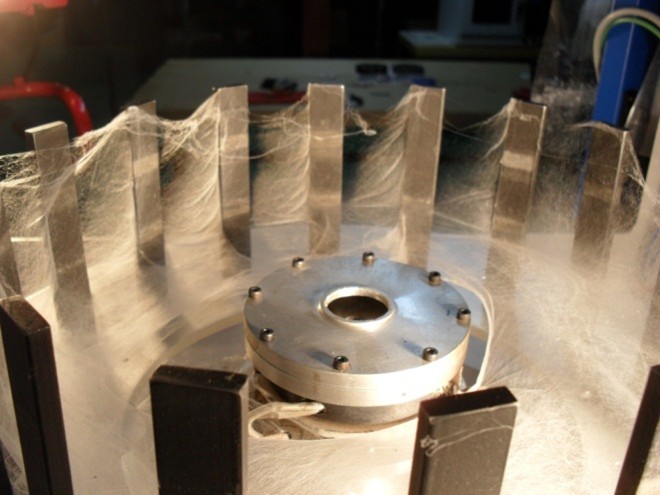

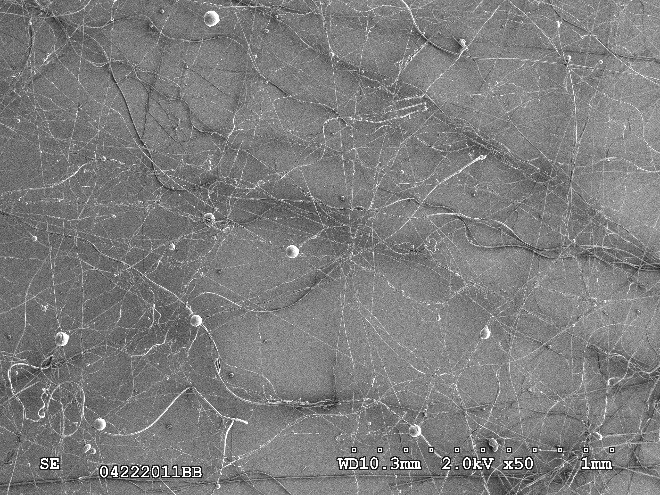

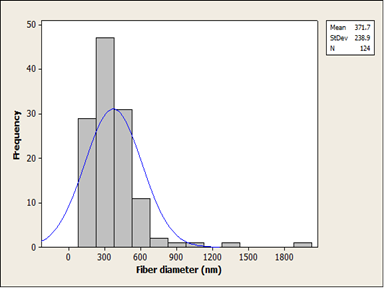

Figure 2 shows the schematic diagram of Cyclone L – 1000M system. This lab scale system has integrated solution spinning and melt spinning capability. Therefore, this system was used to fabricate both solution spun Nylon 6 nanofibers and melt spun Polypropylene nanofibers. For solution spinning, 20 wt% of Nylon 6 solution was spun at 7,000 rpm with a solution spinneret fitted with 30 G needle size at both ends for a time cycle of 1 minute (Figure 3(a)). Figure 3(b) shows the morphology of the Nylon 6 nanofibers collected under present experimental setup. The average diameter was found to be 190 + 84 nm. Fiber size distribution is plotted in Figure 3 (c). In the case of melt spinning, Polypropylene was melted inside a proprietary designed melt spinneret with the set of heater rings by applying radiant heat. Once the desired melting temperature of polymer was achieved, melt spinning was carried out at 12,000 rpm for 30 second time cycle (Figure 4(a)). The spinneret and heating system on Cyclone L – 1000 M is designed to withstand high temperature of up to 450 C. For this study, melt spinning was carried out at 225 C. The corresponding fiber morphology of melt spun Polypropylene and fiber diameter distribution is shown in Figure 4 (b) and Figure 4(c).

Figure 3. Solution spun Nylon nanofibers using ForcespinningTM (a) Photograph of Nylon nanofiber web formed after one minute cycle run (b) SEM image of fiber morphology (c) Fiber size distribution.

Figure 4. Melt spun Polypropylene nanofibers using ForcespinningTM (a) Photograph of Polypropylene nanofiber web formed after 30 second cycle run (b) SEM image of fiber morphology (c) Fiber size distribution.

References

- Lozano, K and Sarkar, K; Methods and apparatuses for making superfine fibers, US20090280325 A1

- Lozano, K and Sarkar, K; Superfine fiber creating spinneret and uses thereof, US20090280207 A1

- Lozano, K and Sarkar, K; Superfine fiber creating spinneret and uses thereof, US20090269429 A1

- Lozano, K and Sarkar, K; Superfine fiber creating spinneret and uses thereof, US20090232920 A1

Author

B. Raghavan, Y. Ner, and K. Lozanob

Fiberio Technology Corporation, Fiberio Technology Corporation, Mechanical Engineering Department, The University of Texas Pan American

-

979-209-9100

Dr. Bharath Raghavan is currently working as a Materials Engineer at FibeRio Technology Corporation, TX. Dr. Raghavan received his Master’s in Paper and Chemical Engineering from Miami University, OH and PhD in Chemical Enginering from University of Akron, OH. His research experiences are in the field of fabricating polymeric and ceramic nanofibers from Electrospinning and Forcespinning™ technology and applying nanofibers in the filter media for air and hot gas filtration applications.