Synthesis of Ceramic Nanofibers

Ceramic nanofibers have many potential applications, such as hot gas filtration, gas adsorption, and electricity generation from engine exhaust gas. The high surface area of nanofibers enhances capture efficiency of sub-micron particles, adsorption and desorption of gases (e.g., hydrogen gas for fuel cell technology) and provides significant advances in thermophotovoltaic (TPV) technology. Functional surfaces, such as catalytic sites, adsorptive sites, and p-n junctions can be designed onto nanofibers and fabricated with the help of different coating technologies.

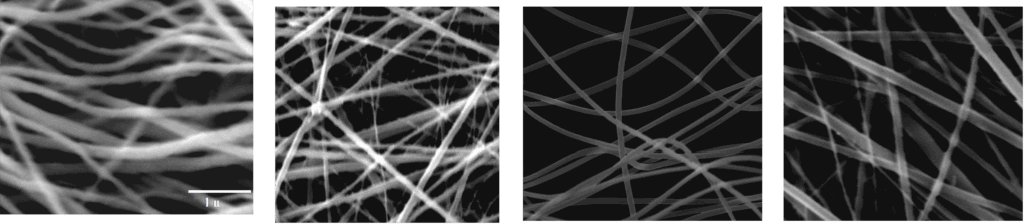

Several types of ceramic nanofibers such as, TiO2, Al2O3, MgO, ZnO, NiO, and binary mixed oxides such as TiO2–Al2O3, ZnO–Al2O3 fibers were synthesized in our laboratory with diameters in the range of 60 to 200 nanometer using the electrospinning process.

The basic principle behind electrospinning is relatively simple which consists of three major components: a high-voltage power supply, a hollow metallic needle, and a grounded conductor that serves as a collector [1-4]. When a sufficient high voltage (1 to 30 kV) is applied to the metallic needle, the electrostatic force within the polymer solution overcomes the surface tension of the solution, causing the ejection of a thin liquid jet from the tip of the needle. The charged jet then undergoes a stretching process resulting from several parameters which includes but not limited to the interactions of external electric field, electrostatic force within the polymer solution, solution viscosity, surface tension of the solution [5]. The liquid jet is continuously elongated and thus gets thinner and thinner until most of the solvent is evaporated. Finally the liquid jet collects on the grounded collector as a web of micro or nanofibers in random orientation. The as-spun fibers are either solely polymeric or composite fibers as both polymeric and ceramic components are present into the fiber matrix.

For making pure ceramic nanofibers, first a viscous polymeric precursor solution of ceramic is made by dissolving metal salts into suitable solvents and then mixing with a polymeric solution to provide the adequate viscosity for electrospinning. This viscous ceramic precursor solution is electrospun at a high voltage of 5-30 kV, gap distance ~20 cm, and a flowrate in the range of 2-30 µl/min. Then the as-spun composite fibers are calcined above the degradation temperature (usually > 550oC) of the polymers to obtain the pure ceramic nanofibers (Figure 1).

References

- Doshi, J., and Reneker, D. H., Electrost. 1995; 35: 151.

- Reneker, D.H., Yarin, A.L., Fong, H., Koombhongse, S., J Appl Phys 2000; 87: 4531–47.

- Theron, A., Zussman, E. and Yarin, A. L., Nanotechnology 2001; 12:

- Lee, K. H., Kim, Y. H., Khil, M. S., La, Y. M. and Lee, D. R., Polymer 2003; 44: 1287.

- Yarin, A.L., Koombhongse ,S., Reneker, D. H., J Appl Phys 2000; 89, 5:3018-26.