Tubular Membrane Filter™ Modules for Metal Contaminated Wastewater Treatment & Reclamation

Background

Industrial processes can often result in waste water contaminated with heavy metals (Hg, Pb, Zn, Ni, Cr, Cu, and Cd) that require treatment prior to discharge or recycling. As we all know, basic treatment technology is chemical precipitation. By adding chemicals into waste water, the chemicals react with heavy metals and form precipitate. Precipitates can then be separated from water with appropriate process. Conventional solid/liquid separation equipment includes many kinds of gravity settling tanks. But gravity settling has some disadvantages due to the separation principle:

- Superfluous coagulant has to be fed into wastewater to form more suspended solids so that the precipitate from heavy metals can be deposited together. Coagulants bring three problems: high operation cost, extreme sludge volume and impurities in coagulants.

- Polymer must be added to wastewater to make suspend solids easier to be settled. Water reclamation is more difficult due to polymer presence

- Separation performance is not good due to a lack of a real barrier.

- Separation performance is not good in high temperatures

Tubular Membrane Filter Modules in combination with chemical precipitation provides excellent reduction of heavy metals (nickel, zinc, copper, lead, chromium, etc). TMF product water (permeate or filtrate) is ready for either disposal into existing municipal waste systems or further treatment for plant reuse/recycle. Treated effluent levels of less than 1 ppm suspended solids and less than 0.1 ppm metals are typical. Cleaning of the TMF modules is simple and involves the use of standard chemicals which will allow many years of service.

Treatment Process

Merits and Drawbacks

- Permeate water is ready for reuse, not just for discharge

- Removal efficiency is excellent with treatment levels more than adequate to meet more stringent discharge standards

- Less space required and easy system expansion is possible, often simply adding membrane modules

- No Polymer Required

- Automatic On and Off Operation

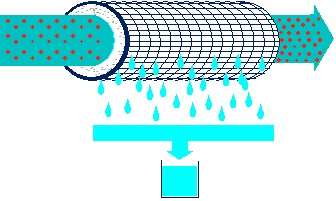

How Does the Tubular Membrane Work?

TMF System Application Data in Heavy Metal Wastewater Treatment

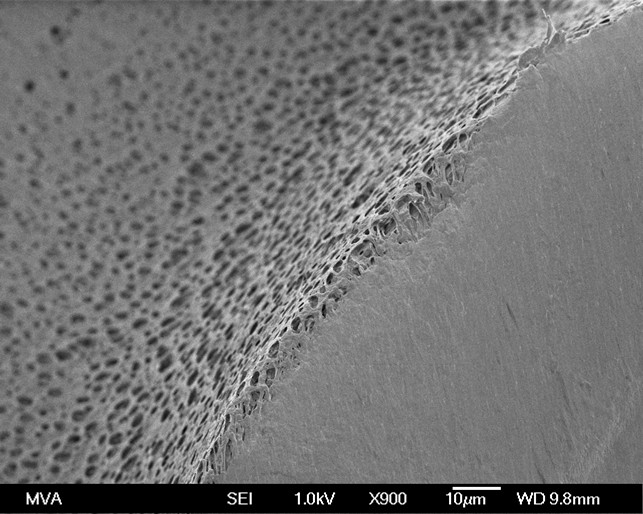

- Typically use membrane modules with 0.1 micron pore size, PE substrate and PVDF membrane, modules with PVC housing

- Filtrated water turbidity less than 1 NTU

- Membrane flux rate is dependent upon raw waste water quality especially organics level

TMF System Equipment Description

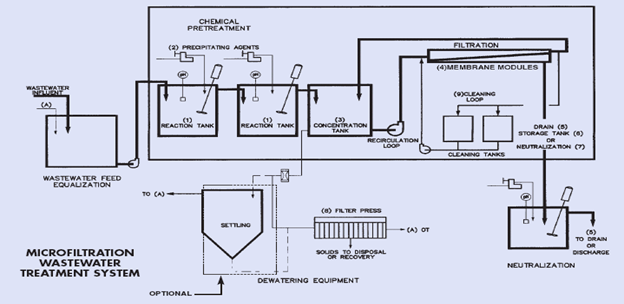

As showed in above flow diagram, a typical tubular membrane separation system will include several parts. Typically these parts are assembled in one or two skids except equalization tank and recirculation tank.

- An equalization tank to hold influent wastewater and to equalize the water quality. Volume of this tank is depended on influent water quantity, quality and fluctuation.

- One or two reaction tanks for pH adjustment, oxidation/ deoxidizing reaction (only for some special metals), coagulant feeding.

- A recirculation tank to hold precipitated wastewater and send to TMF modules via a recirculation pump. Recirculation tank is normally designed to have 2 to 5 minutes hydraulic retention time.

- One recirculation pump, sometimes with a spare pump. Pump capacity will be set according to TMF design calculation report. Generally this pump is designed to give enough flow to keep a high velocity in the membrane module tubes. The pump capacity is normally much higher than actual system capacity.

- One set of TMF modules will be connected in parallel, in series, or both. TMF modules selection and quantity will be decided based on water flow rate and selected flux value.

- One set of CIP system with two cleaning tanks, one cleaning pump and related piping and valve system.

- One air diaphragm pump for sludge transfer

- A local power & control panel with necessary instruments such pressure gauges, flow indicators, flow meters, level meter or switches, turbidity meter.

- Filter press if necessary for concentrated sludge dewatering

TMF System Operation Description

The TMF system has three operation modes: Service, Backpulse and chemical cleaning. A simple description of each operation mode is described below;

Service Mode

The wastewater from upstream flows by gravity or is pumped into a series of reaction tanks with relevant chemicals dosing and necessary pH/ORP monitoring. Gravity flow into the recirculation tank then takes place. The water with precipitated elements is drawn out of the tank by the process (recirculation) pump. The membrane filtration process separates the suspended solids from the liquid. The suspended solids are retained by the membranes and concentrated in the re-circulating stream and returned to the concentration or recirculation tank. Filtrated water that has passed thru the membranes goes to added processing or discharge. Sludge in the concentration tank is sent to filter press periodically by pneumatic pump.

Backpulse Mode

After the system runs under normal conditions for a set period of time, usually 5-30 minutes, the process pump is shut down and an automatic valve on the filtrate piping is closed. A solenoid valve opens, allowing 0.7-1.0 bar of air to push filtrate from the backpulse column, installed on filtrate piping, into the module train for approximately 10 seconds. Because the train is flooded, the air pressure into the piping forces filtered water through the membrane tubes in the opposite direction of the normal filtration flow, dislodging suspended solids that may be fouling the membrane surface.

Chemical Cleaning

After the system has been run for several days or weeks, filtrate flow rate will be decreased. When degradation of performance has reached to a degree, chemical cleaning will be executed manually or automatically, for performance recovery. During CIP, chemical solutions will be sent to the membrane modules via the cleaning pump. Cleaning chemicals including 15% bleach (NaOCl), acids and sodium hydroxide are typically used to dissolve contaminants from the membrane surface.

The TMF system is a very effective process for removal and recycling of metals contaminated waste water. The TMF membrane module is very durable, robust and long lasting allowing very effective treatment and long service life.

Author

Simon Yang

10 years experience in water treatment domain (pure water treatment and wastewater treatment), Simon understands water treatment technology and process design with different process such as multi media filter, carbon filter, softener, RO,CDI&EDI, ion exchange, coagulation, flocculation and biological treatment.

Simon has worked as lead applications engineer for Siemens Water Shanghai as well as Chief Design Engineer for Organo and R&D Applications Engineer for Shanghai Dazhou elec. material company and KaiFeng Air separation Company. Simon is a graduate of Hefei University of Technology where he received a BS degree in Chemical Engineering.