Saturation in Coalescing Filtration

Filtration is a mechanical separation process in which impurities are removed from a gas or liquid stream. Removal of liquid impurities from a gas stream is important in many industrial applications like compressor mist elimination, closed crankcase ventilation, refinery applications etc. There are other separation techniques like centrifugal separator, gravity separator, mist eliminator pads etc. These techniques are quite efficient when the droplet size is quite large. These techniques become less effective for removing liquid droplets in micron and sub-micron size range. Coalescing filtration by fibrous filters is the most effective process to remove these liquid droplets with much higher efficiency and lower pressure drop. These filters are also called as self-cleaning filters. Droplets captured on fibers coalesce together to form bigger drops which eventually drain out of the medium under gravity. Liquid drainage increases with time which equals the loading rate under steady state condition. There is no further increase in accumulation and pressure drop.

Saturation, which is defined as the ratio between volume of liquid and volume of the voids, is an important parameter in gas-liquid filtration. If there is more liquid accumulation, more will be the pressure drop which increases the operating cost of the filters. Maintaining lower pressure is important in any system. Before designing a solution to reduce liquid accumulation, it is important to know the local saturation. If the exact location where the liquid prefers to stay is known, it is much easier to design a system to effectively remove those liquid drops.

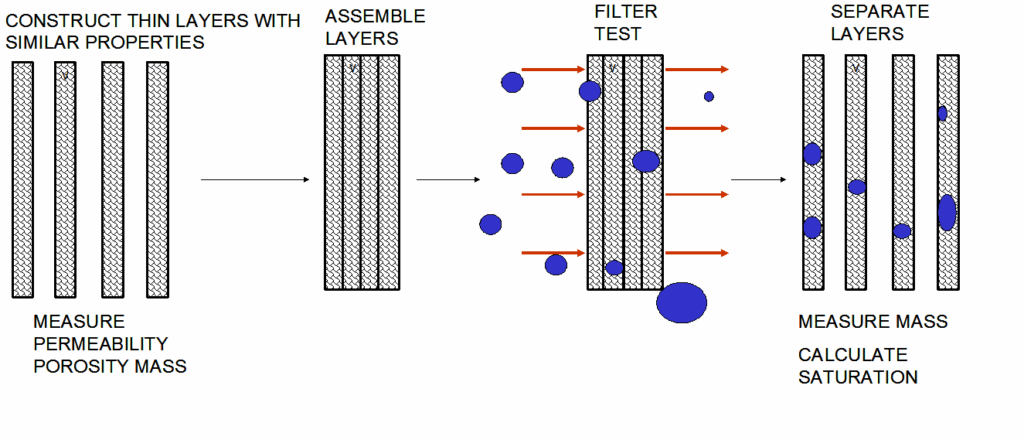

The experimental technique used to measure local saturation is described below in fig. 1.

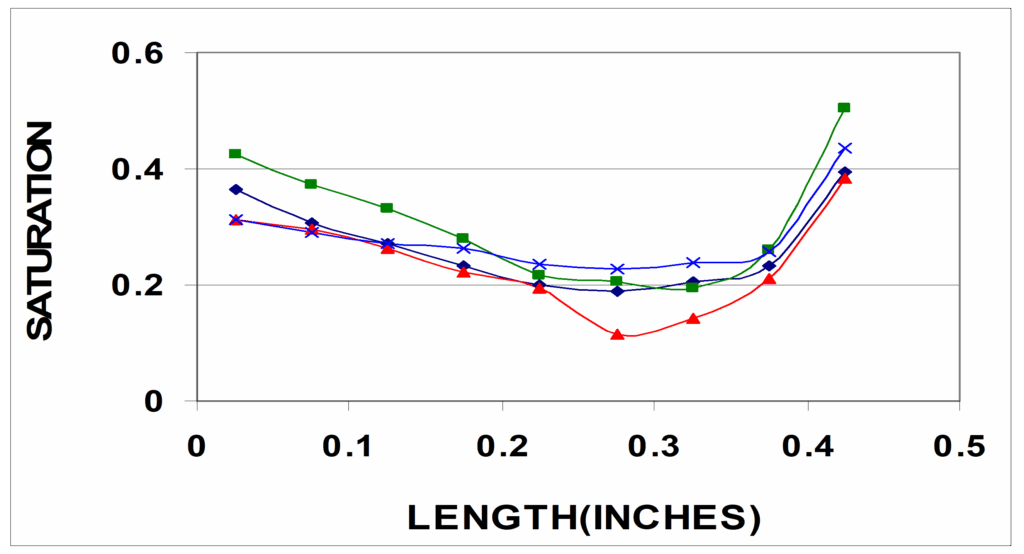

A thick glass fiber medium is made using vacuum forming process and then cut in to several thin layers. The layers are characterized by measuring porosity, permeability and hardness. The mass of each layer before the experiment is measured. Few layers, with similar properties, are assembled together and tested in filter testing experiment using propylene glycol aerosol. When the system reached steady state, the layers are removed quickly and the mass of each layer is measured again. The volume if liquid in each layer is measured using the difference in mass before and after the experiment. Since the pore volume is known, saturation can be easily determined. Fig. 2 shows the saturation profile with 9 layers assembled together.

This figure clearly shows that the saturation is high at the entrance and the exit surfaces with minimum saturation closer to the exit surface. At the entrance, there is large no. of small drops which do not move quite well. At the exit, there is imbalance in surface tension effect which makes the bigger drops stick to the surface. This experiment clearly presents the trend of liquid accumulation inside a glass fiber medium. This result will be quite useful in designing a system to remove the liquid drops from the filter medium and improve its overall performance.