Roll Stock Formed Membrane Overview

Microporous membranes used for filtration and separations have a history dating back for over a hundred years, but began to grow significantly in the 1950’s and 60’s. These membranes were followed by commercial development of Ultrafiltration (UF) and Reverse Osmosis (RO) membranes in the 1960’s and ‘70’s. The major difference between microporous membranes and UF and RO membranes is in the structure of membrane. The use of market microporous membranes roll stock totals about $1.5 billion value worldwide with the market growing at 5-10 percent per year, depending upon the market segment. UF and RO membranes, got a later start, but are growing at 10-25 percent per year depending upon the market segment and represent roll stock of over $2 billion worldwide in value prior to formation into a filter. UF and RO membranes are largely configured and used in spiral wrap modules.

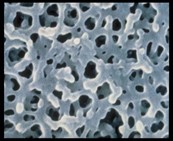

Microporous membranes are thin films from 25 to as high as 125 micron thick and have clearly visible pores under an electron microscope are typically rated from as low 0.02 micron absolute and as high for practical purposes at 3.0 micron nominal. However, the vast majority of the membranes manufactured and used are 0.2 micron absolute, a sterilizing grade to remove bacteria from a fluid stream. Typically these membranes are used as cut disks for laboratory filtration, as pleated cartridges or capsules in the process industries or laminated to needlefelt fabrics in baghouse filtration, where the nominal pore size is about 3.0 micron.

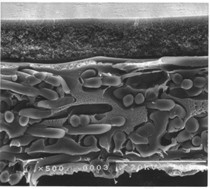

UF membranes transition for microporous membranes with visible pores under a microscope below 0.02 micron to dense films without pores. Typically, the polymers used to make the dense films are compounded to provide a defined molecular weight cutoff to ab-sorb and subsequently de-sorb a liquid under high-pressure to reject a solid of a defined size. UF membrane modules are used in whey production, fruit juice concentration and many other uses. RO membranes are denser films than UF membranes, like UF membranes usually used in spiral modules using extremely high pressure, most notably known for rejecting of brine or salt from seawater known as desalination.