Electrospinning of Polymer Nanofibers

Electrospinning is a process in which fibers of nanoscale or submicron scale are generated, as the electrified jet (composed of a highly viscous polymer solution) is continuously stretched due to electrostatic repulsions between the surface charges and the evaporation of solvent (1,2). Its versatility finds applications in many fields ranging from filtration, biomedical, electronics, electrical and textiles. In the field of filtration fibrous materials used as filter media provide advantages of high filtration efficiency and low air resistance (3).Coalescence filtration is used increasingly in industries to capture oil droplets as small as 0.3 micron. One major factor in filtration is the fitness of the filter media which can be increased by adding electrospun nanofibers so that the channels in the filters can meet the scale of the particles to be captured. The filtration efficiency is significantly increased because of very large surface area to volume ratio (this ratio for a nanofiber can be as large as 1000 times of that of a microfiber), flexibility in surface functionalities, and superior mechanical performance (e.g. stiffness and tensile strength) compared with any other known form of the material and high porosity(4). Nanofibers have been used in coalescence filtration, biofiltration, as pulse- clean cartridges for dust collection and in cabin air filtration of mining vehicles.

The following are the steps are performed to obtain polymer nanofibers.

- Firstly the solution to be electrospun is prepared by dissolving the polymer in a suitable solvent in a particular weight ratio (typically about 15 to 20% polymer). Let us consider the electrospinning of Polyvinylpyrollidone (PVP). PVP is dissolved in ethanol at a concentration of 4 % (w/w).

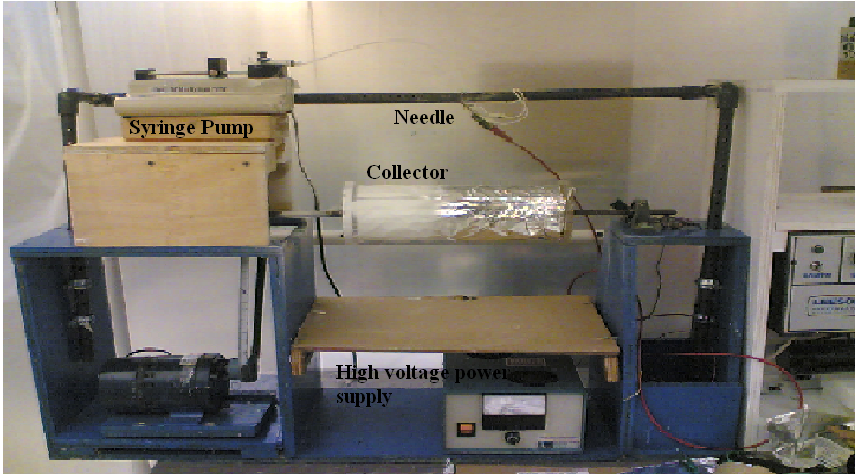

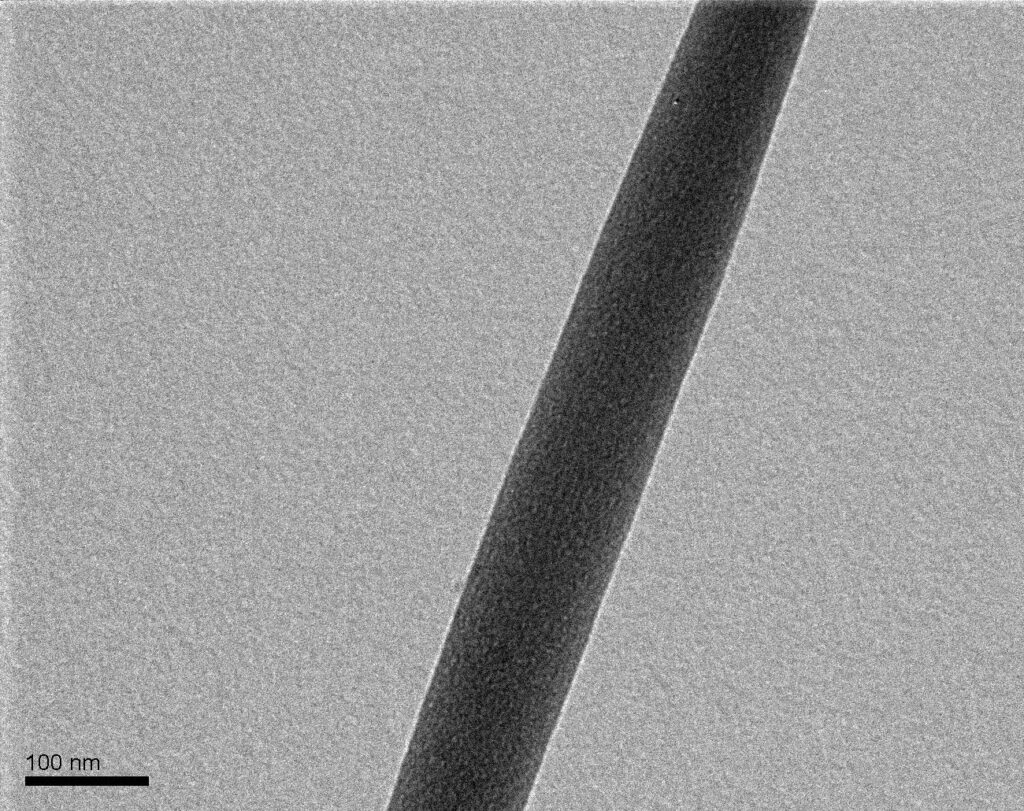

- Second, the solution is loaded into a 5 mL syringe. The syringe is placed on a syringe pump which pumps the solution at a fixed flow rate to a stainless steel needle. A high voltage is applied to the needle while the collector is grounded. The collector is typically placed about 10 to 20 cm from the needle. Figure 1 shows the collector (aluminum foil) on a rotating cylindrical drum. A nonwoven nanofiber mat is formed on the collector which is carefully removed for subsequent use. The fibers have diameters in the range of 50 to 200 nanometers (Figure 2). In the case of PVP, the PVP was pumped at a flow rate of 2 µL/min and a voltage of 20 kV was applied at a distance of 20 cm from the aluminium foil collector.

Many polymers such as polyethylene oxide(PEO), polyvinyl alcohol(PVA), nylon, polyurethanes (PU), polycaprolactone (PCL) etc. have been electrospun using this method.

References

- Reneker DH, Yarin AL, Fong H, Koombhongse S. Bending instability of electrically charged liquid jets of polymer solution in electrospinning. Journal of Applied Physics 2000; 87: 4531-4547.

- Li D, Xia Y. 2004. Electrospinning of Nanofibers: Reinventing the Wheel? Advanced Materials.16:1151-1170.

- Tsaia PP, Schreuder-Gibson H, Gibson P. 2002. Different electrostatic methods for making electret filters. Journal of Electrostatics.54:333–41.

- Huang Z.M, Zhang Y.Z, Kotaki M and Ramakrishna S. 2003. A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Composites Science and Technology. 63: 2223-2253.